The 91 Newman 40WRKB Travel Trailer is an excellent choice for adventurers seeking the comfort of a home on wheels. One of its most appreciated features is the slide-out mechanism, which provides additional living space when parked.

This guide will walk you through everything you need to know about the slide-out mechanism—from understanding its components, maintaining sequence integrity, and troubleshooting common issues to performing routine maintenance and safe usage tips. Whether you’re new to trailer ownership or a seasoned traveler, this manual will serve as your go-to resource for keeping your slide-out in top shape.

Understanding the Slide-Out Mechanism in Your Trailer

Introduction to the Slide-Out Mechanism

Slide-outs are a staple feature in many travel trailers, adding valuable square footage for lounging, dining, or sleeping. However, due to the complexity of the mechanism, regular maintenance is essential to ensure smooth and consistent operation.

Why It’s Essential: Slide-out mechanisms add mechanical complexity, meaning more moving parts that need care to prevent wear or failure over time.

Benefits of Slide-Outs:

Enhanced Living Space: Slide-outs provide additional room when stationary, allowing for more comfortable movement inside the trailer.

Flexibility: Expanding your trailer’s interior with a slide-out gives you more options to configure your space for various activities.

Key Features of the Slide-Out System

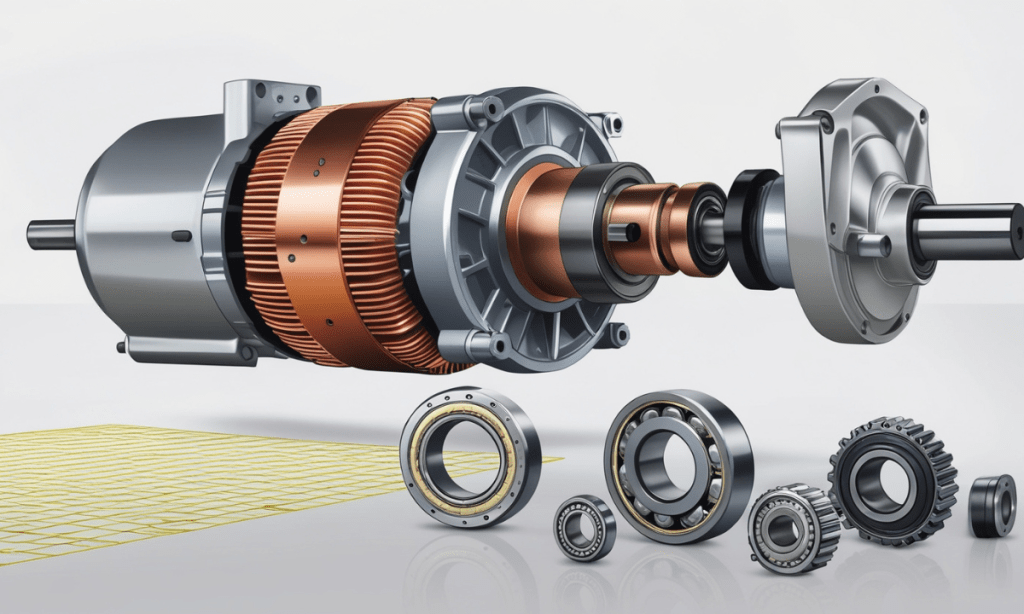

Each slide-out system comprises several key elements designed to work together seamlessly. Knowing these components helps you understand how each part contributes to the overall function.

Motor-Driven Operation: The slide-out relies on a motor to extend and retract with ease. This motor drives the sliding mechanism, eliminating the need for manual effort.

Tracks and Bearings: These ensure the smooth movement of the slide-out along its rails, preventing any snagging or friction issues.

Electrical Controls: Most modern slide-outs are controlled electronically, allowing easy extension and retraction with a single button.

Manual Override Option: In the event of a power failure, many slide-outs are equipped with a manual override that allows you to operate the slide-out manually.

Essential Components of the Slide-Out System

Breakdown of the Slide-Out Parts

The slide-out system is an intricate assembly of parts working together to extend and retract smoothly. A basic understanding of these components will help you troubleshoot and maintain your slide-out effectively.

Major Parts of the Slide-Out System:

- Motor: This is the heart of the slide-out, providing the force needed to move the structure in and out.

- Tracks and Bearings: These guide the slide-out along its path, ensuring it stays aligned and operates smoothly.

- Electrical Wiring: Powers the control panel and motor, enabling efficient operation.

- Control Panel: Allows you to extend and retract the slide-out with the push of a button.

Key Components and Their Roles

| Component | Function | Maintenance Tips |

|---|---|---|

| Motor | Powers slide-out movement | Check connections regularly |

| Tracks/Bearings | Support and guide the slide-out movement | Lubricate annually |

| Electrical Wiring | Connects components for power flow | Inspect for fraying or wear |

| Control Panel | Allows user control over slide-out | Test buttons and functions |

- Motor: Responsible for moving the slide-out mechanism. Maintenance Tip: Regularly check connections to ensure a stable power flow.

- Tracks and Bearings: Ensure smooth sliding. Maintenance Tip: Lubricate once a year to prevent wear.

- Electrical Wiring: Connects the power from the battery to the slide-out motor. Maintenance Tip: Inspect for any signs of wear, fraying, or exposure to prevent electrical issues.

- Control Panel: The central hub for operating the slide-out. Maintenance Tip: Test buttons and functions periodically to ensure responsive controls.

Sequence Integrity in Slide-Out Operations

Importance of Sequence Integrity in Mechanisms

Sequence integrity, or the orderly functioning of all components, is critical for slide-outs to work properly. When parts operate out of sequence, the slide-out can jam or fail to extend and retract smoothly.

Causes of Sequence Interruptions

- Component Misalignment: Parts that are out of alignment can cause interruptions in the sequence, making the slide-out stutter or jam.

- Power Interruptions: Loose wiring or faulty connections can disrupt the power flow, leading to incomplete movements.

- Motor Malfunctions: Overheating or aging motors may fail to drive the slide-out fully in or out.

Common Slide-Out Problems and Their Solutions

Identifying and Resolving Issues in Slide-Out Mechanisms

Common slide-out issues can usually be identified during regular inspections and addressed with straightforward fixes.

Common Issues and Solutions:

- Slide-Out Won’t Extend or Retract

- Cause: Power interruption, wiring issue, or motor malfunction.

- Solution: Check electrical wiring, motor connections, and control panel.

- Unusual Noises During Operation

- Cause: Dirt or debris in tracks, or worn-out bearings.

- Solution: Clean and lubricate the tracks, and replace bearings if necessary.

- Power Fluctuations

- Cause: Loose or frayed wiring connections.

- Solution: Inspect and secure all wiring connections to prevent fluctuations.

- Slide-Out Not Moving Evenly

- Cause: Misaligned tracks or uneven weight distribution.

- Solution: Realign tracks and ensure load distribution within the slide-out section.

Step-by-Step Slide-Out Maintenance Guide

Routine Maintenance Steps

Regular maintenance ensures that the slide-out remains operational and reduces the risk of unexpected breakdowns.

Step-by-Step Maintenance:

- Inspect the Motor and Control Panel

- Look for Visible Wear: Examine the motor and control panel for any signs of damage.

- Test Control Buttons: Ensure all buttons respond correctly.

- Lubricate Tracks and Bearings

- Apply Lubricant: Use a suitable lubricant for the track material to keep the slide-out moving smoothly.

- Reduce Friction: Regular lubrication prevents wear and tear on the slide-out tracks and bearings.

- Check Electrical Connections

- Inspect for Fraying: Examine all wiring for signs of wear or fraying.

- Tighten Connections: Secure any loose connections to maintain consistent power flow.

Motor and Bearing Health in Slide-Out Operations

Importance of Motor and Bearing Health

The motor and bearings are vital to the slide-out’s reliable operation. Regular checks help identify early signs of wear, allowing timely intervention.

Signs of Motor or Bearing Wear

- Inconsistent Motor Operation: The motor may work intermittently or fail to retract the slide-out fully.

- Grinding Noise: Grinding or squeaking sounds usually indicate bearing wear, which requires lubrication or replacement.

Motor and Bearing Maintenance Checklist

| Task | Frequency | Steps |

|---|---|---|

| Inspect motor for wear | Every 6 months | Visual and auditory check |

| Lubricate bearings | Annually | Use high-grade grease |

| Check for grinding noises | During operation | Replace worn bearings |

Electrical System Checks for Slide-Out Mechanisms

A properly functioning electrical system is critical for the smooth operation of the slide-out mechanism in your 91 Newman 40WRKB travel trailer. This system powers the motor, control panel, and other key components, so it’s important to perform regular checks to prevent power issues, which could lead to costly repairs or even complete failure of the slide-out. Routine electrical diagnostics help you spot potential issues early, ensuring your slide-out remains in good working condition.

Step-by-Step Electrical Diagnostics

Turn Off the Main Power Supply

Safety First: Always begin by disconnecting the main power supply to avoid any risk of electric shock.

Battery Disconnection: If your trailer uses a battery system, ensure the battery is also disconnected before you start inspecting the electrical system.

Inspect the Control Panel

Check Button Responsiveness: Press each button on the control panel to confirm it’s functioning correctly. Unresponsive buttons could indicate an internal wiring issue or worn-out switches.

Indicator Lights: Most control panels come with indicator lights that display the operational status of the slide-out. If the lights are dim or flickering, this could be a sign of loose connections or a failing power source.

Clean the Control Panel: Dust or debris can sometimes cause buttons to stick or malfunction. Use a soft cloth to clean the control panel and remove any build-up.

Examine the Wiring System

Look for Visible Damage: Carefully inspect all visible wiring around the slide-out mechanism. Frayed or damaged wires are a common cause of power issues, leading to interruptions in the slide-out sequence.

Check for Corrosion: Corrosion can form around wire connections, especially if the trailer has been exposed to moisture. If you see any corrosion, clean it gently with a wire brush or a solution specifically made for electrical contacts.

Secure Loose Connections: Loose wiring connections can lead to intermittent power, which can cause the slide-out to stop mid-operation or move inconsistently. Tighten any loose connections, but avoid overtightening to prevent damage.

Test for Power Consistency

-

- Multimeter Test: Use a multimeter to check for consistent voltage across the wiring system. This will help you confirm that there’s a stable power flow to the slide-out motor and control panel.

- Voltage Range: Refer to your trailer’s manual for the appropriate voltage range for your slide-out mechanism. Inconsistent or low voltage can be a sign of a failing battery or damaged wiring.

Inspect the Motor’s Power Connection

-

- Check Power Cables: The motor relies on a steady flow of power to operate the slide-out mechanism. Inspect the power cables leading to the motor to ensure they’re securely connected and free from any wear or damage.

- Listen for Motor Function: When activating the slide-out, listen to the motor. If it sounds strained or inconsistent, it might be a sign of a voltage drop or wiring issue that needs attention.

Key Electrical Components to Check

Here’s a breakdown of the main components in the electrical system and what to look for during your inspection:

| Component | Inspection Steps | Common Issues |

|---|---|---|

| Control Panel | Test all buttons and indicator lights; clean surface | Unresponsive buttons, dim lights |

| Wiring | Check for fraying, corrosion, and loose connections | Power loss, intermittent issues |

| Battery | Ensure battery holds charge; check connections | Voltage drops, low power output |

| Motor Power Connection | Inspect cables for wear, listen for consistent operation | Strained sounds, voltage issues |

Additional Electrical System Maintenance Tips

- Routine Cleaning: Dust and debris can interfere with the control panel and wiring connections. Clean these areas regularly with a dry cloth.

- Check Battery Health: If your trailer’s battery isn’t holding a charge, it might be time to replace it. Weak batteries can lead to inadequate power for the slide-out mechanism.

- Secure Loose Wires: Use zip ties or clamps to keep wires organized and secure, especially in high-movement areas where vibration may cause them to loosen over time.

- Inspect After Moisture Exposure: After heavy rain or if the trailer has been in a humid environment, inspect the wiring and motor for any signs of corrosion or moisture damage. Moisture can be particularly damaging to electrical connections.

Common Signs of Electrical Issues in Slide-Out Mechanisms

- Unresponsive Control Panel: If the buttons don’t respond when pressed, it could be due to a loose connection or internal wiring fault within the panel.

- Inconsistent Movement: The slide-out may stutter or pause mid-operation, which is often caused by fluctuating voltage or loose connections.

- Flickering Indicator Lights: This is typically a sign of poor connectivity in the wiring system or a power source issue.

- Unusual Motor Sounds: Grinding, clicking, or inconsistent motor sounds may indicate a problem with the motor’s power supply or internal motor wear.

Using the Manual for Troubleshooting

Maximizing the Slide-Out Manual

The slide-out manual contains essential troubleshooting tips and instructions, making it a valuable resource for every trailer owner.

Key Sections of the Manual

- Setup and Installation: Details on setting up and calibrating the slide-out system.

- Troubleshooting Guide: Common issues and step-by-step solutions.

Upgrading Slide-Out Components

Considerations for Upgrading Slide-Out Parts

When parts wear out, it’s often more practical to upgrade than to repair. Choose compatible parts to avoid complications.

Tips for Selecting Compatible Upgrades

- Opt for OEM Parts: Original Equipment Manufacturer parts are more likely to be compatible.

- Check Specifications: Make sure any replacements meet the slide-out’s specifications.

Common Issues and Solutions Table

Slide-Out Problems Reference Table

Use this table as a quick guide for troubleshooting common issues.

Table 3: Slide-Out Troubleshooting Reference

| Problem | Cause | Solution |

|---|---|---|

| Slide-out doesn’t move | Motor failure | Inspect motor and wiring |

| Unusual noise | Debris in track | Clean and lubricate |

| Power issues | Loose wiring | Secure connections |

Preventing Wear and Tear in Slide-Out Components

Best Practices for Preventing Wear

Routine maintenance and timely repairs are essential for preventing premature wear in your slide-out system.

Maintenance Tips for Longevity

- Keep Tracks Clean: Prevent debris buildup by cleaning the tracks regularly.

- Lubricate Moving Parts: Reduce friction by applying lubricant, extending the life of moving components.

Safety Tips When Operating Slide-Outs

Key Safety Practices for Slide-Outs

Safety is crucial when using slide-outs to prevent accidents and ensure the longevity of your trailer components.

Safe Operating Tips

- Keep Area Clear: Ensure the slide-out path is free from obstacles.

- Avoid Overloading: Don’t exceed the weight capacity when the slide-out is extended.

Understanding Slide-Out Technical Terms

Key Terms in Slide-Out Maintenance

Technical terms can make maintenance and troubleshooting easier to understand.

Glossary of Essential Terms

- Alignment: The positioning of parts for smooth operation.

- Lubrication: Applying grease to reduce friction between moving parts.

Seasonal Maintenance for Slide-Outs

Preparing Your Slide-Out for Winter and Summer

Seasonal maintenance keeps your slide-out operational throughout the year.

Seasonal Slide-Out Maintenance Checklist

| Season | Maintenance Task | Additional Notes |

|---|---|---|

| Winter | Apply anti-freeze to motor | Protects motor during freezing temps |

| Summer | Shade the slide-out when parked | Reduces heat-related wear |

My Opinion

In my opinion, maintaining the electrical system of a slide-out mechanism is crucial for hassle-free operation and a longer lifespan of the trailer. Regular checks of the control panel, wiring, and motor connections can prevent common issues and help spot potential problems early. A small investment in routine diagnostics can save significant repair costs down the line.

I believe it’s essential to clean connections, check for corrosion, and ensure everything is securely fastened. This attention to detail adds reliability and safety to each trip. Proper care gives me peace of mind, knowing my trailer will operate smoothly when I need it.